Production

Extrusion

Aluminum profiles for various sectors and usage purposes are produced in our extrusion lines. The extrusion process is briefly; It can be summarized as forcing the heated aluminum billet to pass through a mold and while taking the shape of the mold and extending it into profiles.

There is 1 press line in our extrusion department. The aluminum tickets used in our extrusion lines are first class and we produce 1xxx, 5xxx and 6xxx series alloys as well as special alloy profiles. In our facility, we have an archive of over 22,000 various product molds.

In our extrusion lines, aluminum profiles up to 9 mt. length can be produced in different alloys for architectural or industrial use. Aluminum profiles up to 9 m length can be manufactured.

Aluminum profile extrusion is a delicate process measured in microns. The parameters of all equipment in our production facility are controlled by high-tech devices and are recorded in our company-specific software to ensure traceability.

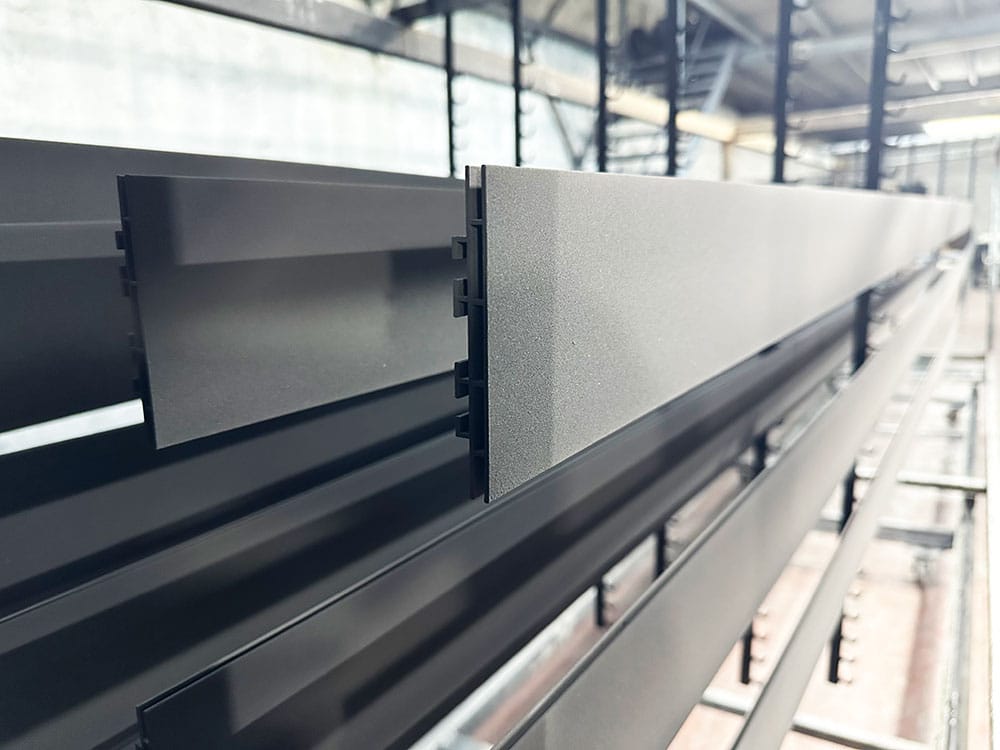

Dyehouse

With the state-of-the-art automatic system of our electrostatic powder coating facility, special color profiles requested by our customers are processed, as well as RAL colors of different brightnesses. Profiles up to 8060 mm long can be processed in our pools whose investment has been completed.

The quality of our facility has been registered with the European QUALICOAT certificate. The surface of the painted profiles can show resistance against the UV effect of the sun rays as well as its resistance against corrosion.